Problem Statement:

A leading client required last-mile delivery to a clustered customer base with an average one-way distance of 85 km. The client had two operational strategy to perform the same:

- Direct Delivery from Central Warehouse

This would increase daily travel distances (more than 170 km round trip), inflating vehicle running costs significantly.

- Establishing a Warehouse

While this would bring deliveries closer to the customer, the setup and operational costs of a new warehouse would sharply raise overall expenses. It also requires high operational involvement from the team.

Current Situation:

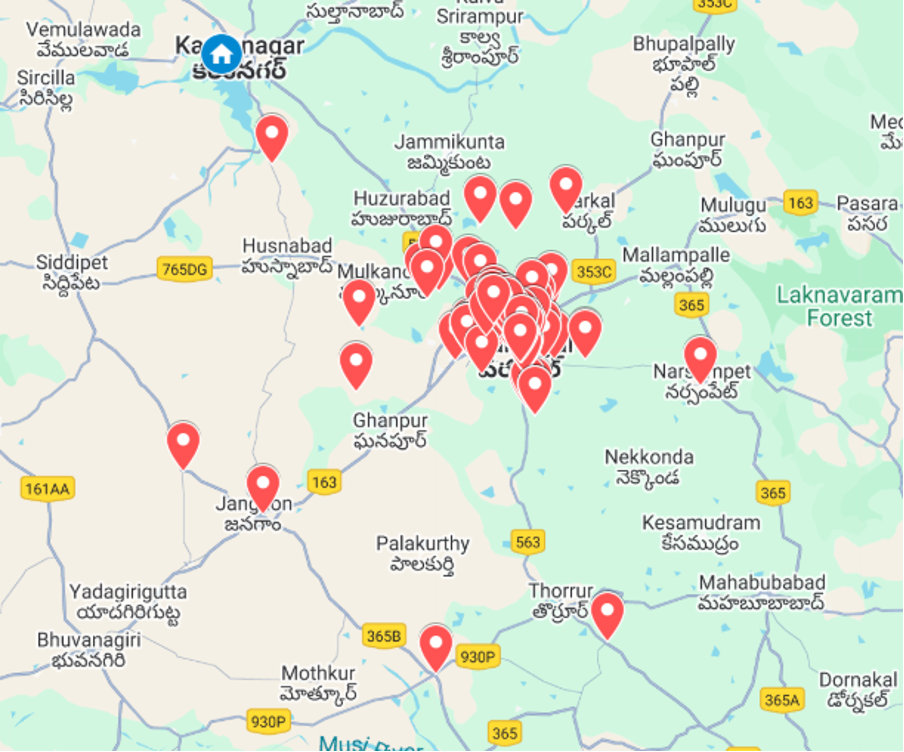

Map 1: Map Showcasing the warehouse and pin codes that it serves.

OORJAA’s Solution: Cost-Efficient Cross-Docking

OORJAA introduced a cross-docking strategy, where goods are shipped from the central warehouse to a strategically located cross-dock center, from which they are dispatched to nearby customers. The model operates on a per-kg billing structure, ensuring cost stability even with fluctuating demand.

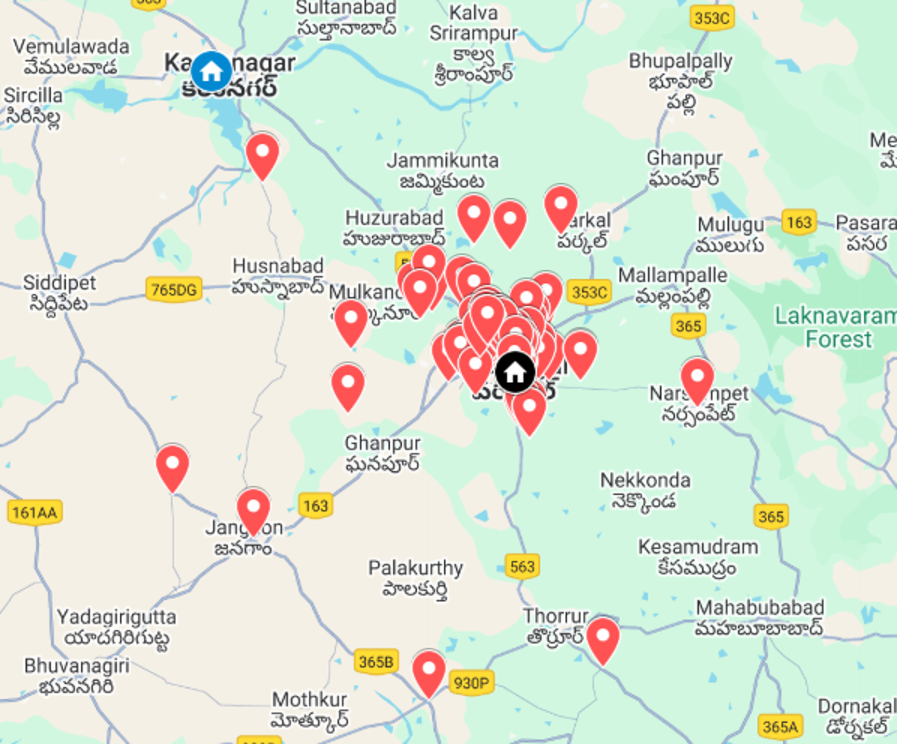

Map 2: Map showcasing the cross-dock at the strategic location, servicing last mile from the cross-dock.

The Operation involved three stages:

- Mid Mile

- Cross-dock

- Last Mile

1. Mid Mile – Strategic Stock Movement

OORJAA facilitates the strategic transfer of goods from the central warehouse to the cross-docking center. This ensures that inventory is brought closer to the customer clusters without the need for a local warehouse setup.

Benefits:

- Fuel consumption is reduced by maximizing the efficiency of larger vehicles and reducing the numbers of vehicle by full truckload (FTL) shipments for stock transfers.

- Ensures timely replenishment based on demand patterns

2. Cross-Dock – Efficient Sorting & Re-routing

At the cross-docking centre, OORJAA handles sorting, consolidation, and quick turnaround of shipments for last-mile delivery. The cross-dock acts as a temporary, transit-based hub — not a storage facility — ensuring rapid flow of goods.

Benefits:

- Eliminates storage costs and delays

- Supports dynamic routing and consolidation

- Maintains consistent per-kg costs regardless of volume fluctuations

3. Last Mile – Intelligent Local Delivery

Using its technology-enabled optimized routing and regional expertise, OORJAA ensures that the last mile delivery is carried out efficiently. The proximity of the cross-dock to customer locations allows for faster, more reliable deliveries.

Benefits:

- Reduces average delivery distance from 85 km to just 20 km

- Improves customer satisfaction with timely deliveries

- Allows bundling of multiple deliveries and trips

- Reducing the cost due to the lower fuel consumption due to shorter average distance

Impact:

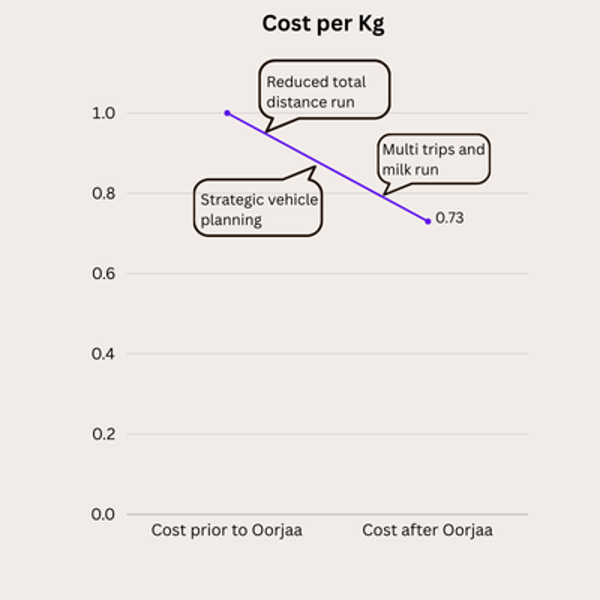

The cost graph illustrates the substantial reduction in logistics expenses in cost per kg achieved through OORJAA’s cross-docking model.

- Before OORJAA’s Solution: Costs were significantly higher due to long-distance direct deliveries (85 km one way) from the central warehouse to individual customer clusters. This model involved high fuel consumption, increased vehicle usage, and inefficient route planning.

- After Implementing Cross-Docking: The introduction of a strategically located cross-dock reduced the average delivery distance to just 20 km. Combined with optimized full truckload (FTL) transfers and a per-kg billing structure, overall logistics costs dropped sharply. This approach ensures efficiency, even during demand fluctuations, by minimizing idle capacity and stabilizing pricing.